Are you tired of dealing with the pains of metal candy molds for your gummy manufacturing process?

You wouldn’t be the first.

But what if I told you there was a way to save time, money, and effort — all while achieving unique, high-detail designs for your gummies?

The answer is platinum silicone gummy molds.

Sound too good to be true? Not to our clients, it doesn’t.

I’ve had dozens of folks over the years who have converted from metal to silicone, and they’ve seen firsthand how silicone candy molds completely revolutionize and revitalize operations.

In this blog post, I’m going to share with you everything my clients already know: the outsize benefits of using silicone molds for your gummy production, and why they’re a total game-changer for your business.

Let’s dive in.

Recipe Compatibility

One of the biggest advantages of silicone molds is recipe compatibility.

Metal molds require precise dialing in of the recipe for the unit to operate correctly.

However, many machines that run metal molds don't always work as advertised.

This can be a huge pain and can cost gummy manufacturers a massive amount of time and money.

On the other hand, silicone molds offer far more in recipe compatibility. They allow for a wider range of recipes, and are less prone to causing issues when it comes to setting the gummies.

Ejection Pins

Another issue with metal molds is the use of ejection pins.

These pins can cause divots in the gummies, which can be seen through the sugar coating.

This makes it impossible to run any design that requires a symbol or logo on the face – since that's precisely where the pins were.

Needless to say, this can be a huge pain when passing regulatory muster, and a total dealbreaker when running custom designs for your white label contracts.

Moreover, the pins can deform the final product, making it difficult to achieve a consistent look and quality.

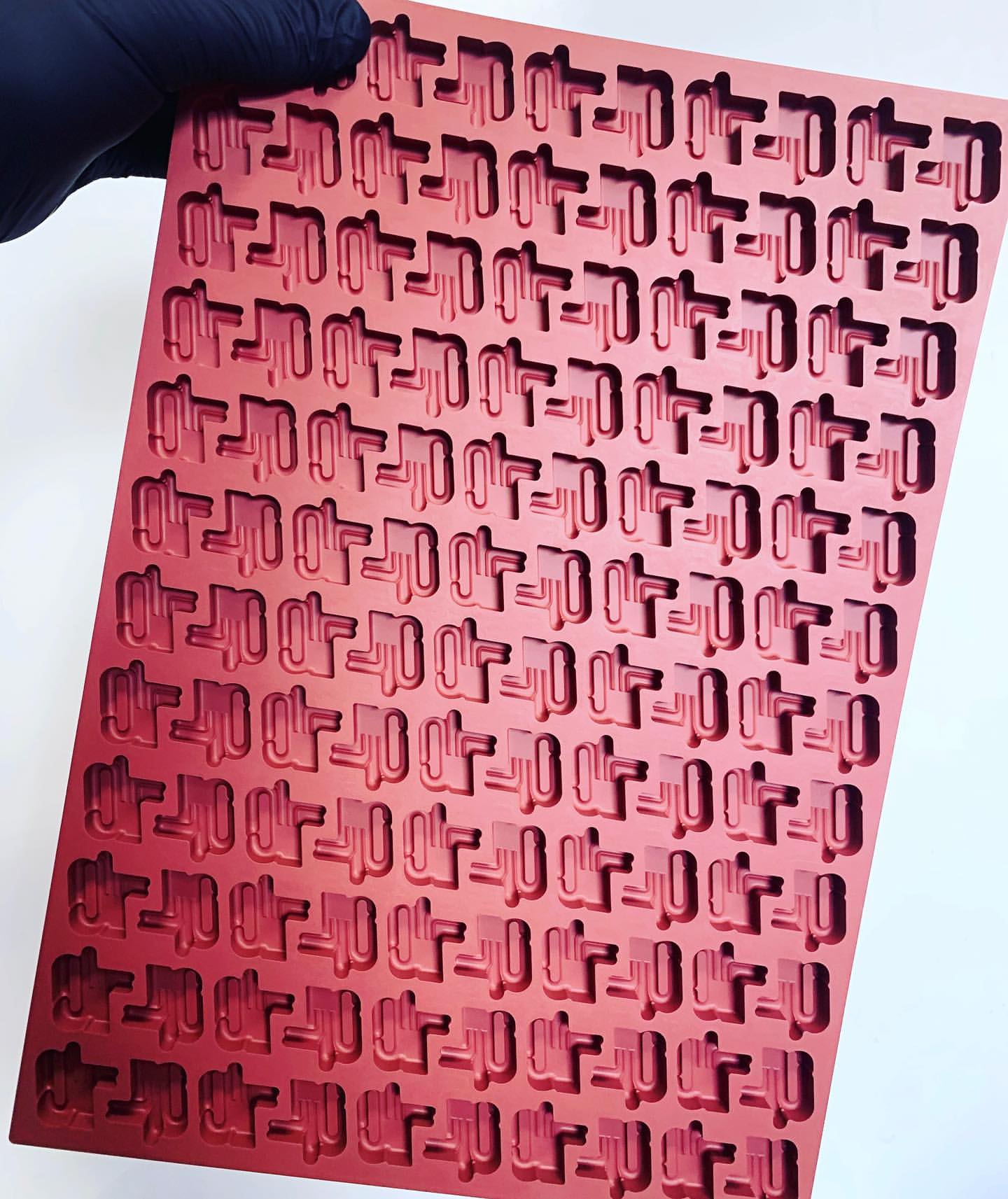

In contrast, silicone molds don't use ejection pins at all —and as a result, there is less deformation of the final product.

Check out our IG to see for yourself just how easy it is to work with platinum silicone Rose Pro molds– all completely ejection pin-free.

Cleaning

Cleaning metal molds after a run is another pain point for gummy manufacturers.

(Although our clients tend to describe this issue in rather more… colorful language.)

Candy gets stuck in the pins or down in the corners/details of the mold, and since they don't bend, it's tough to get in there and to properly clean it out.

It is, by all accounts, incredibly annoying– but more to the point, this cleaning difficulty adds a ton of unnecessary labor cost to the manufacturing process.

In contrast, cleaning silicone molds is far easier.

Since they are flexible, gummy manufacturers can very easily access all corners and details of the mold, making cleaning a breeze. If you really want an easy time of it, simply rises and run them through your industrial dishwasher.

This not only saves time but also reduces labor costs.

Lead Times

Lead times for metal molds can be frustratingly long.

When gummy manufacturers do get custom metal molds made, it can take up to three times as long as silicone molds.

Additionally, metal molds do not capture fine detail, which is crucial for the unique, high-detail gummies that are so popular these days.

On the other hand, silicone molds have a shorter lead time and can capture fine details with ease.

This makes them the ideal choice for manufacturers who need to produce high-quality, intricate designs in a short amount of time.

Maintenance

Maintenance is yet another issue with metal molds.

Because metal molds are locked into a single depositing method - a depositing machine - the fault tolerance for any gummy operation rolling one of these systems is not especially great.

In fact, these systems go down frequently, and this can significantly impact production, since manufacturers are completely tied up until the mold system is fixed.

But use of silicone molds are far more reliable and offer far more flexibility in depositing method.

Even if a depositor system does go down, gummy manufacturers who have wisely invested in silicone molds can still fill by hand if necessary.

This flexibility provides an invaluable backup option that has saved many manufacturers from a production shutdown.

In fact, filling by hand - or running a Flood & Scrape table - can be just as efficient and scalable as a depositor, all on it’s own. Check out our articles on the subject to learn more.

Pivotability

The ability to quickly pivot operations is critical for infused production.

Whether you're producing your own brand or white labeling for other companies, it's all about being able to run smaller batches with different designs in tandem and change-up on a dime.

Metal molds were created for the conventional candy industry. They work well for producing large batches of the same design, but are not so useful for producing small batches of unique designs quickly.

Like taking a hammer to a screw— it’s just the wrong tool for the job.

Much better off using silicone molds that offer more flexibility and can produce unique candies of various designs quickly and efficiently.

–

Silicone molds have become the go-to option for many gummy producers due to their many benefits over metal candy molds.

From recipe compatibility to design flexibility and ease of maintenance, silicone molds provide a superior option for producing high-quality gummies at scale.

If you're looking to upgrade your gummy manufacturing process, we invite you to browse our wide selection of stock mold designs. With options ranging from classic bears and worms to unique shapes and sizes, we have a mold for every need. And if you have a custom design in mind, don't hesitate to contact us to discuss your vision.

Investing in silicone molds can be a game-changer for your gummy production, and we're here to help you take that next step. Don't settle for outdated metal molds that limit your design possibilities and require excessive maintenance.

Choose the superior option with silicone molds and see the difference for yourself.