So, you want to make gummies, but you’re not sure what type of gummy molds will work best for your purposes.

We totally understand!

Today’s marketplace is filled with an overwhelming number of options - from flimsy injection molds to multi-million dollar automated systems.

In fact, there’s so many types of gummy molds, it can make a lot of companies want to quit before they even start.

But don’t! Cannabis and CBD gummies are one of the top revenue drivers for white label manufacturers and cannabis brands alike. And with just a little insight, you too can have your own high-output gummy kitchen up and running in no time.

Why take our word for it?

Well, we’ve done this before.

In fact, since 2019, we’ve helped set up over a thousand kitchens with gummy molds, molds for chocolate, recipes, equipment, and comprehensive consulting programs.

In that time, we’ve seen companies make just about every gummy mold mistake you can imagine. But we’ve also seen those same companies correct those mistakes (with a little help) and go on to generate MILLIONS in profits.

So, let’s get down to brass tacks and explore a few of the reasons experienced cannabis companies choose silicone gummy molds for their manufacturing processes.

In this article, we’ll discuss:

Why Quality Silicone Gummy Molds Eradicate Bottlenecks

The Impact Of Silicone Gummy Molds On Labor Turnover

How Easy Design & Quick Leads Empower The Cannabis Industry

The Compatibility Advantages of Silicone When Scaling

Let’s dive in by examining the most crucial advantage of all: demolding.

Why Quality Silicone Gummy Molds Eradicate Bottlenecks

If you’ve been involved in manufacturing of any kind, you’ve heard the word:Bottlenecks.

For those who don’t know, bottlenecks are any part of a production process that is inefficient to a point that it severely limits the overall output of the operation.

These inefficiencies can result in lost revenue and unhappy workers. They can also occur at virtually any point in your workflow, but with cannabis and CBD gummies the primary bottleneck is almost always the same culprit.

That culprit is demolding speed AKA how quickly you can get your gummies out of the mold.

Why is this?

Well, way back when the legal (read: at scale) cannabis industry was just getting started, newbie manufacturers took stock of their gummy mold options.

They were faced with a lot of the same questions companies are faced with now:

What kind of molds do I buy?

Should I buy cheap or expensive molds?

Does the mold-style or type of material matter?

At this point there was NO established industry guidance and very few high-efficiency candy molds on the market. So, as you might guess, a lot of these new manufacturers naturally opted for the cheaper, more readily available injection-style molds.

Note: Injection-molded silicone gummy molds are the flimsy rubber molds often used by weekend warriors and home cooks. One of the best ways to identify this style is by the visibly protruding cavities on the bottom of the mold.

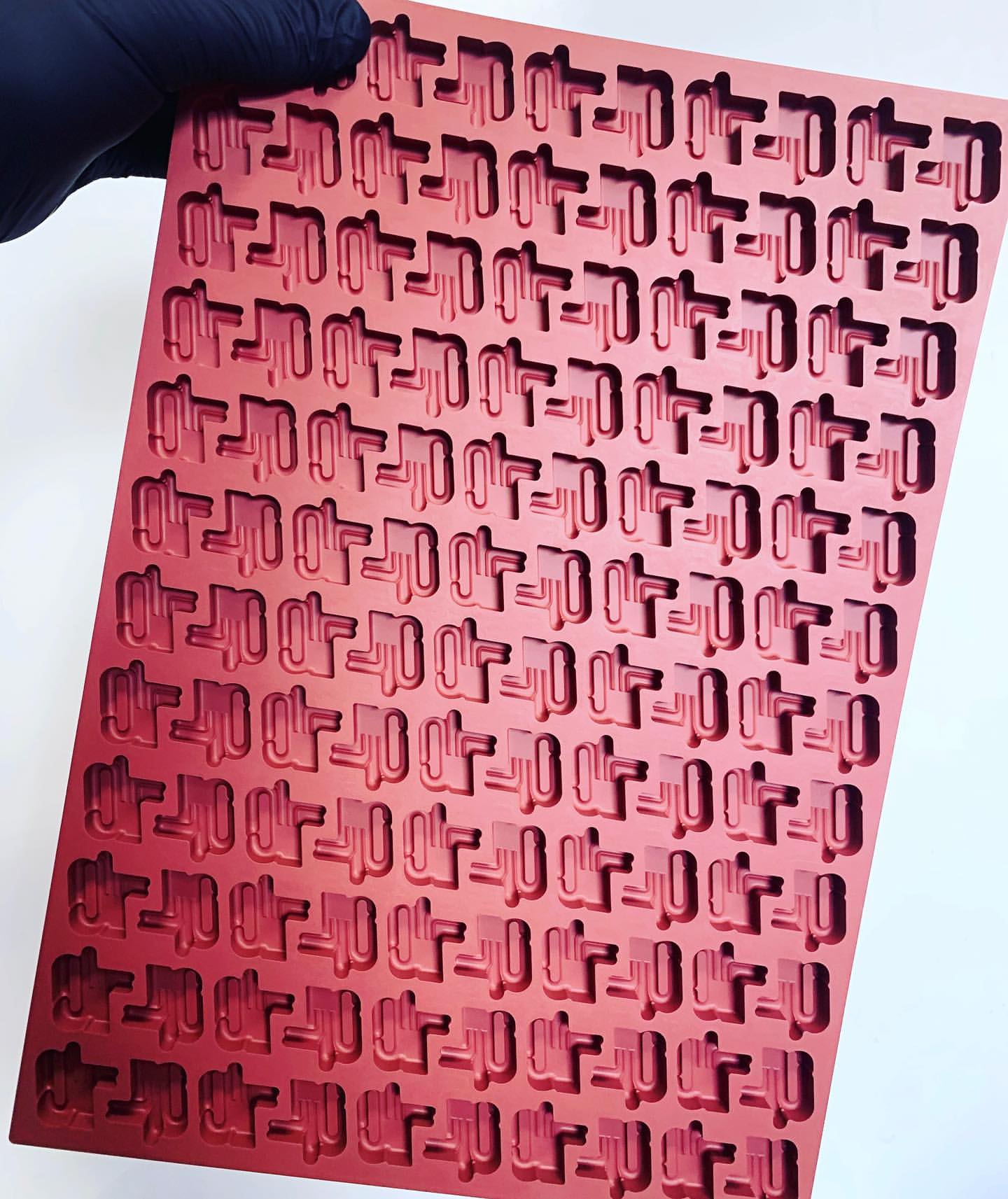

They look like this:

Little did these manufacturers know that while injection molds are much cheaper to manufacture and therefore generally more affordable, they are also much MORE expensive to operate.

This is because, when demolding, the ergonomics of the gummy mold require an operator to use their finger to poke each gummy out one-by-one.

Not only is this an excruciatingly slow process, it can also result in deformed gummies and high worker turnover (more on that last one later).

AND since labor is the number one expense in gummy manufacturing, a slow demolding process means significantly higher costs and, by extension, lower profit margins.

And here’s the catch: This same exact mistake is still being made today.

And sadly, it can derail operations for months. Sometimes even years.

So, how do you avoid this headache?

If you’re running any sort of volume (think 100 gummy batches and above), you want to invest in professional-grade gummy molds.

They look like this…

Flat bottom molds, you make the rockin world go round

Flat bottom molds, you make the rockin world go round

These professional gummy molds have flat bottoms that cause the molds to be demolded in an entirely different way.

Rather than poking out each gummy one-by-one, these molds allow you to demold the whole mat in two easy motions:

First, lay the mat upside down on a clean work surface.

And second, peel the mat back like a bedsheet and swipe the gummies out.

That’s it.

In our tests, we’ve found that using the above technique with professional quality flat-bottom molds is over 300% more efficient, on average, than using the hobbyist injection molds.

And our clients swear by it. Peep our reviews.

We’ve helped hundreds of companies make the leap from injection to professional flat-bottom molds, but we have never even heard of any company going the other way. It simply never happens.

Get rolling with flat-bottom molds, and you’ll quickly see why.

The Impact Of Silicone Gummy Molds On Labor Turnover

Eliminating the prime bottleneck of every start-up gummy operation is clearly a killer advantage to using silicone molds, but it is far from the only one.

Use of professional grade silicone molds also contribute to a happier and healthier workforce, and decreased labor turnover.

How?

Easy to see when you consider the alternative.

Just imagine a typical workday for your workers if you’ve built your operation around injection style molds.

Using their finger or thumb, they pop out one gummy. Then another. Then another.

…Then another.

Over and over and over again.

And if your business is doing well, which hopefully it is… They keep popping them out, over and over and over again. And again. And AGAIN.

This monotonous focused strain on your workers’ hands can have serious long-term health implications, and could lead to issues like carpal tunnel syndrome.

And I can tell you on good authority that worker turnover tends to be much higher among companies using injection style molds versus our clients who have made the leap to our Rose Pro molds.

Working with flat-bottom silicone candy molds is much easier, takes much less time, and is a more *holistic* motion for your workers’ hands, so it tends to be easier on their joints.

How Easy Design & Quick Leads Empower The Cannabis Industry

Time is money.

The one cliche that no one questions because everyone in business knows it’s true.

Especially in our industry where the ground is always shifting, and new brands often have to pivot hard - and fast.

Well this is another reason so many of the most successful new brands prefer silicone molds for gummies:

Speed.

Not only is silicone an extremely versatile material that molds to even the most complicated designs and keeps its shape for years…

It is also easy to design and work with.

This means that experienced mold manufacturers like yours truly can keep the design, pour, and cure times to the absolute minimum.

And this means quick lead-times for our clients.

Say you’re going through a brand refresh, and need unique gummy molds custom made in the shape of your new complicated logo. Oh, and you need them next week?

We got you. Custom molds for gummies are our stock in trade.

Ours is a fast moving industry that’s seeing most of its organic mid-market growth fueled by muscular social media brand presence.

It’s true that production, especially the manufacture of physical goods, naturally trails behind the pace of marketing in virtually every industry. And this is only getting more true with social.

But for gummy companies who invest in professional grade silicone molds?

Their product keeps pace with their vision. This is everything.

Time is money, right? Don’t waste yours by buying cheap molds.

Because the simple truth is this: they are only cheap *now* and will waste more and more of your time the longer you put off the move to flat-bottom silicone molds.

The Compatibility Advantages of Silicone When Scaling

But silicone molds aren’t only the no-brainer option when first starting out in the industry.They’re also the smart choice when scaling operations as well.

The molds you invest in during the early stages MUST have the ability to adapt to your evolving processes – especially as automation and equipment buildout become more relevant considerations.

Every one of Dark City’s custom mold systems, for example, is designed to be ideal for hand pouring and for use in any automation ecosystem you want to invest in down the line.

Other gummy candy molds made with sub-optimal materials, like metal gummy molds, tend to be locked into the machine they were designed for.

Luckily, this is yet another area where flat-bottom silicone molds excel.

Like the silicone they are made of, flat-bottom mold systems are robust and flexible, and work with an array of pour methods, automated depositors, and demolding machines.

You simply cannot outgrow your flat-bottom silicone mold investment.

Instead, it grows with you.

–

Given the wide range of benefits in using flat-bottom silicone molds, it’s no wonder they’ve become the go-to option for up-and-coming candy brands.

But maybe you still have questions. No problem!

The experts at Dark City Molds are ready to partner with you. Drop us an email today, or give us a call the old fashioned way – we’ll gladly help you determine how silicone gummy molds can level-up your business.