I’m going to tell you what I tell my new clients all the time. You DO NOT have to break the bank to compete at scale in this industry.

It’s really true.

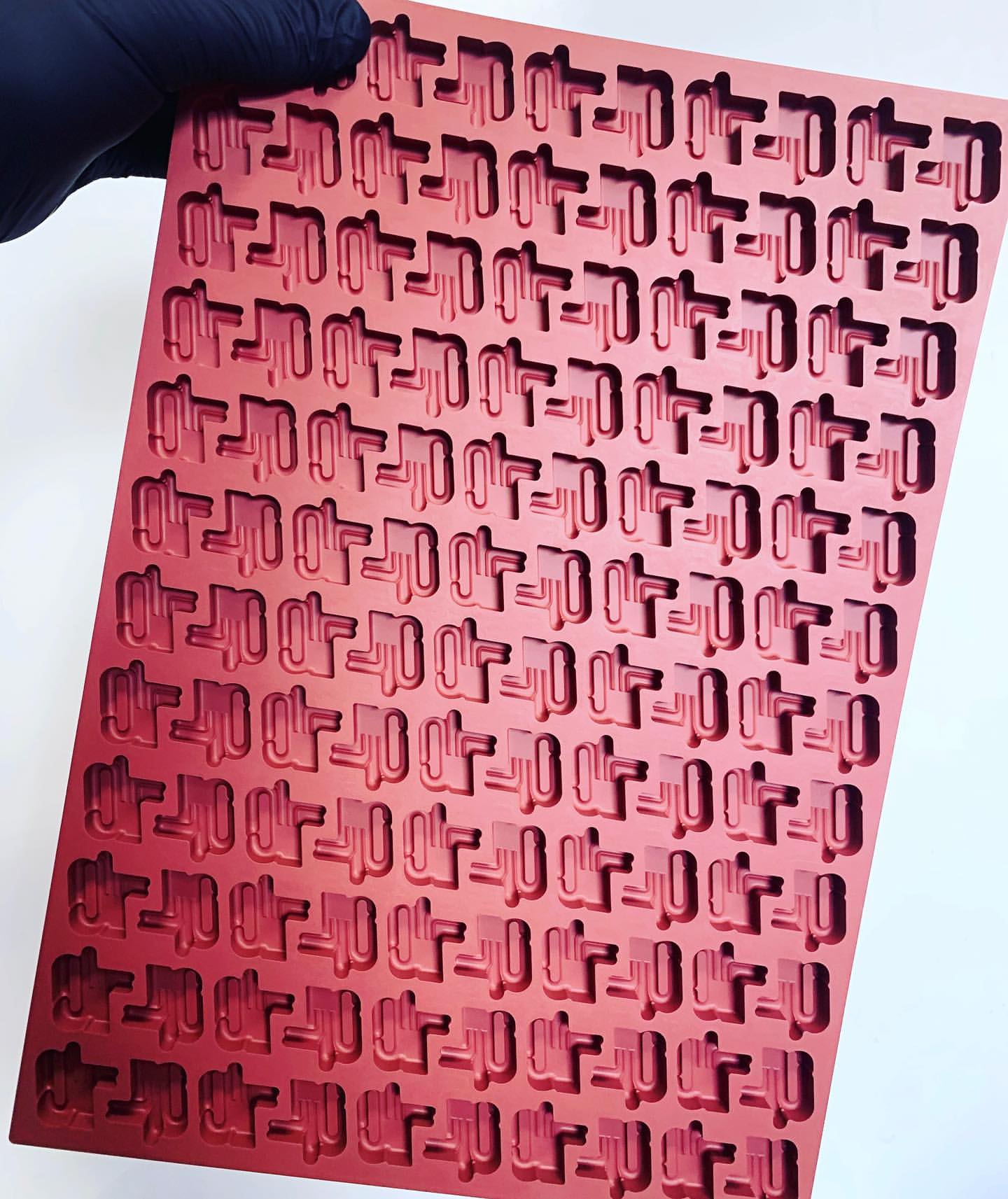

You can be producing hundreds of thousands of candy pieces month after month, with just couple of strong stainless steel tables, a no-compromises platinum silicone mold system, and a rock-solid and unique gummy recipe.

But I have to tell you: many people assume it’s just gotta be harder than this…

…and they come straight to me with their doubts and hesitations.

So before you throw down all of your start up capital on that fancy gummy making machine, allow me to dispel the 3 main hesitations I hear from clients who are considering running with Flood & Scrape instead of a depositor.

Hesitation #1: “What about the loss?”

People will often worry that they're going to waste excess slurry Flood & Scraping.

The truth is: you will lose slurry even using a mechanical depositor. This is due to contact loss inside the hopper and the depositing nozzles themselves.

And there’s very little you can do to mitigate this.

That is, unless you Flood & Scrape.

You see, with F&S, the only surfaces your gummy mixture touches are your cook pot, transfer bowl, and your molds. That’s it. No other surfaces for excess slurry to get stuck to.

And if you adjust your batch as you go, you'll develop what we call a Cavity Perfect Setup – which means that the amount you pour on the table tends to equal the total volume of your cavities on your grid.

Tl;dr – Flood & Scrape is significantly less wasteful than using a depositor.

AND it gets more efficient over time, as you develop a deeper understanding of your product. No more loss.

Check out this Insta Reel to get a feel for how straightforward this is.

Hesitation #2: “I have a skinning problem”

Skinning is that thin layer of gummy slurry that can build up over the top of your molds.

This can create a web that holds your gummies into your mold and makes them harder to demold.

This can be a problem with any depositing method, as the underlying cause of skinning has to do with the fundamentals of your recipe.

Therefore, skinning can be fixed or significantly reduced by adjusting elements of your recipe.

(Check out this article, or get involved with DCM's Gold Standard Recipes & SOPs to cultivate a much stronger sense of what the likely culprits are here.)

This is why understanding your chemistry really matters. Shout it from the rooftops, people!

Hesitation #3: “Can I ensure regular Dosing?”

Beyond achieving a fully homogenized batch in the cooking stage, accurate dosing is all about ensuring a uniform volume of your gummies.

Machine depositors achieve this mechanically, of course. The nozzles are set to deposit an exact amount of slurry with minimal margin for error.

But like any mechanical component, these nozzles can be susceptible to wear and can be unfortunately failure-prone.

When Flood & Scraping, by contrast, all that is required to get uniform volume consistently is high quality platinum silicone molds.

If you’re running with Dark City Molds’ systems, all of your cavities are going to be exactly the same size.

Scraping over the top with a flat object like a kitchen-safe food scraper ensures perfect dosing every single time.

And frankly, many depositors aren't that accurate.

--

The simple truth is this: you don't need a gummy machine to compete at scale in the candy industry.

Flood & Scrape can be just as efficient and cost-effective, with significantly less waste.

Don't let common hesitations about excess slurry, skinning problems, and irregular dosing hold you back from considering this method.

So why not give it a try? Check out our collection of stock designs and contact our team today to get started with Flood & Scrape and take your candy production to the next level.