I’m often asked: what sets Dark City Molds’ products apart?

And why is DCM the custom silicone mold manufacturer of choice for so many gummy makers in the industry?

Of course there’s plenty to say on the topic of our unique performance materials, but the truth is that’s not the only advantage of DCM’s gummy mold systems.

As I often tell people, it’s the “strategic design,” in addition to our no-compromises Rose Pro material that situates our molds at the head of the pack.

So today, I want to demystify a core aspect of DCM’s strategic design philosophy by outlining the Top 3 approaches to gummy piece design.

By understanding these options, you can make an informed decision that aligns with your brand vision and operational efficiency.

More after the jump.

Loving what you’re reading? Get more gummy wisdom by following us on Instagram.

The “Pure Silhouette” Custom Gummy Mold

The first option for piece design is to create a mold that closely resembles the literal silhouette of the source design (your desired shape for your gummy).

This approach is very often used successfully for logos, but you can take this tack with any type of source design.

However, due to the physical constraints of gummy manufacturing, this approach usually requires significant modification of the source design.

The shape needs to be "unibodied" – that is, lacking any dramatic appendages that could lead to breakage during demolding, packaging, or shipment.

While it is possible to create such custom gummy molds, it is far from ideal from an operational standpoint, and we generally advise against it.

So while the prospect of rendering your source design in glorious 3D is tempting, the high risk of breakage generally means that this option is off the table for most gummy makers.

The “Standard Geometry” Custom Gummy Mold

On the other end of the spectrum, you can opt for a source design that is placed on a simple backing.

This approach involves embossing or debossing the source design on a standard geometric shape such as a circle, square, rectangle, or oval.

By choosing a backing that closely matches the silhouette of the source design, you can maintain brand distinction while minimizing the risk of breakage.

This option offers the advantage of showcasing the complete source design without sacrificing structural integrity.

However, it may limit the flexibility of choosing a unique shape that perfectly represents your brand identity.

Though we’ve seen this work with many of our industry partners to great effect, it’s also true that many find the “standard” silhouette too delimiting for their brand.

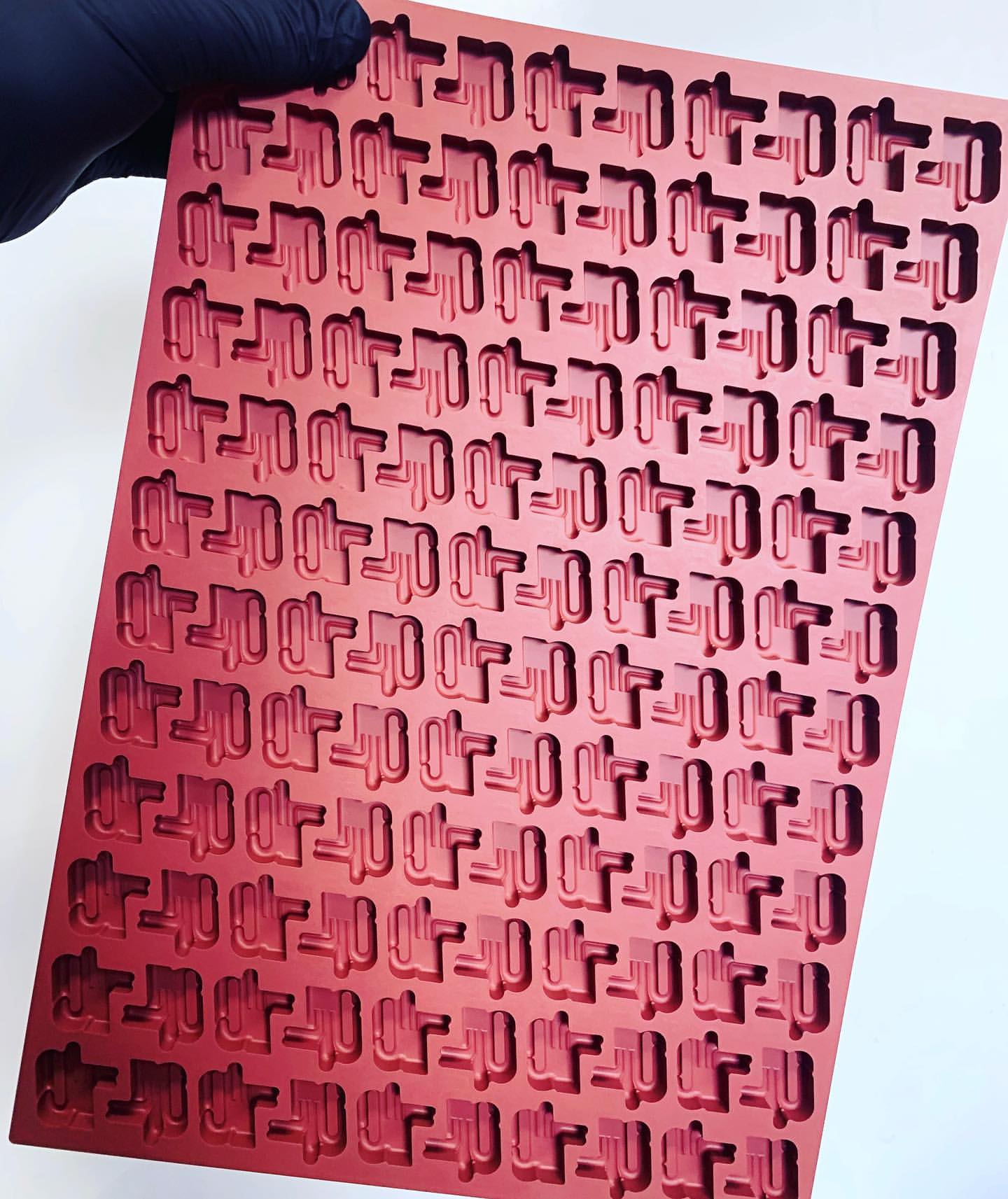

The “Offset Perimeter” Custom Gummy Mold

A middle ground solution that often proves to be a popular option with clients is what we call an “offset perimeter.”

This approach involves creating a custom, non-standard, irregular shape that mostly follows the perimeter of the gummy.

However, in areas of the source design that are more peninsular, we incorporate "webbing" to provide additional support.

This design approach allows you to preserve the unique silhouette of your gummy, ensuring that your vision remains distinct– while also, crucially, staying operationally mindful.

The offset perimeter strikes a balance between maintaining brand identity and considering the practical aspects of mold production and demolding efficiency.

As with the first two options, the operational benefits extend past the efficiency of demolding and mitigation of loss.

They also confer a reduction in breakage risk in packaging and shipment as well.

By choosing a design that minimizes vulnerable appendages or provides additional structural support, you can enhance the overall durability of your gummies.

This not only protects your product integrity but also ensures customer satisfaction when they receive your gummies in pristine condition.

Combining these operational advantages with the maximal preservation of the source design's silhouette– and it becomes evident why many gummy manufacturers opt for the offset perimeter approach.

This design approach option allows you to strike a balance between artistic expression and practical considerations.

And it enables you to deliver gummies that are visually appealing, structurally sound, and aligned with your brand's unique identity.

–

At Dark City Molds, we understand the importance of strategic design in creating exceptional custom gummy molds.

Whether you choose the pure silhouette, a backing with a standard shape, or the offset perimeter approach, our team of experts is dedicated to crafting high-quality molds that elevate your gummy production.

We take into account your brand vision, operational efficiency, and the overall success of your business.

DCM is here to support you by creating molds that not only showcase your unique gummy designs but also optimize your production processes and ensure the durability of your products.

This is also the primary motivation in the development of our Gold Standard Recipes & SOP’s. Along with your strategically designed molds, having a professional gummy recipe plays a determining role in the efficiency of your workflows, the shelf stability of your product, and thus, the health and profitability of your business.

So why is Dark City Molds the custom silicone mold manufacturer of choice for gummy makers?