Today, I want to share with you an often overlooked aspect of your gummy production workflow: preparing your gummies for packaging.

While packaging gummies may seem like a straightforward task, there are important considerations to ensure efficiency and cost-effectiveness.

(Interested in the infused gummy game, but only just getting started? Have no fear! We’re here for you. Check out this article for a ton of helpful information.)

Gummy Packaging Approaches

In the infused industry, hand counting is probably the most common method for packaging gummies.

While semi- or fully automated packaging options exist and can work well, they come with their own complexities and are often specific to the type of packaging used.

For example, filling Mylar bags differs from filling tins, which in turn differs from filling boxes.

The choice of packaging method ultimately depends on your brand's presentation preferences.

But when you're just starting out, I recommend beginning with hand packaging.

This allows you to gain practical experience and understand the nuances of the process before considering automated alternatives.

However, it's important to note that, while automated options are the more costly path, hand counting gummies do come with cost and time considerations, as well.

Gummies, with their various shapes and sizes, can be challenging to count accurately and efficiently at scale – no matter which strategy you choose.

So, what's the solution?

Strategically Designed Custom Candy Molds

Depending on the specifics of your operation, there may be a simple hack that can help reduce the expenses associated with hand counting.

Many of my clients have successfully utilized the following strategy:

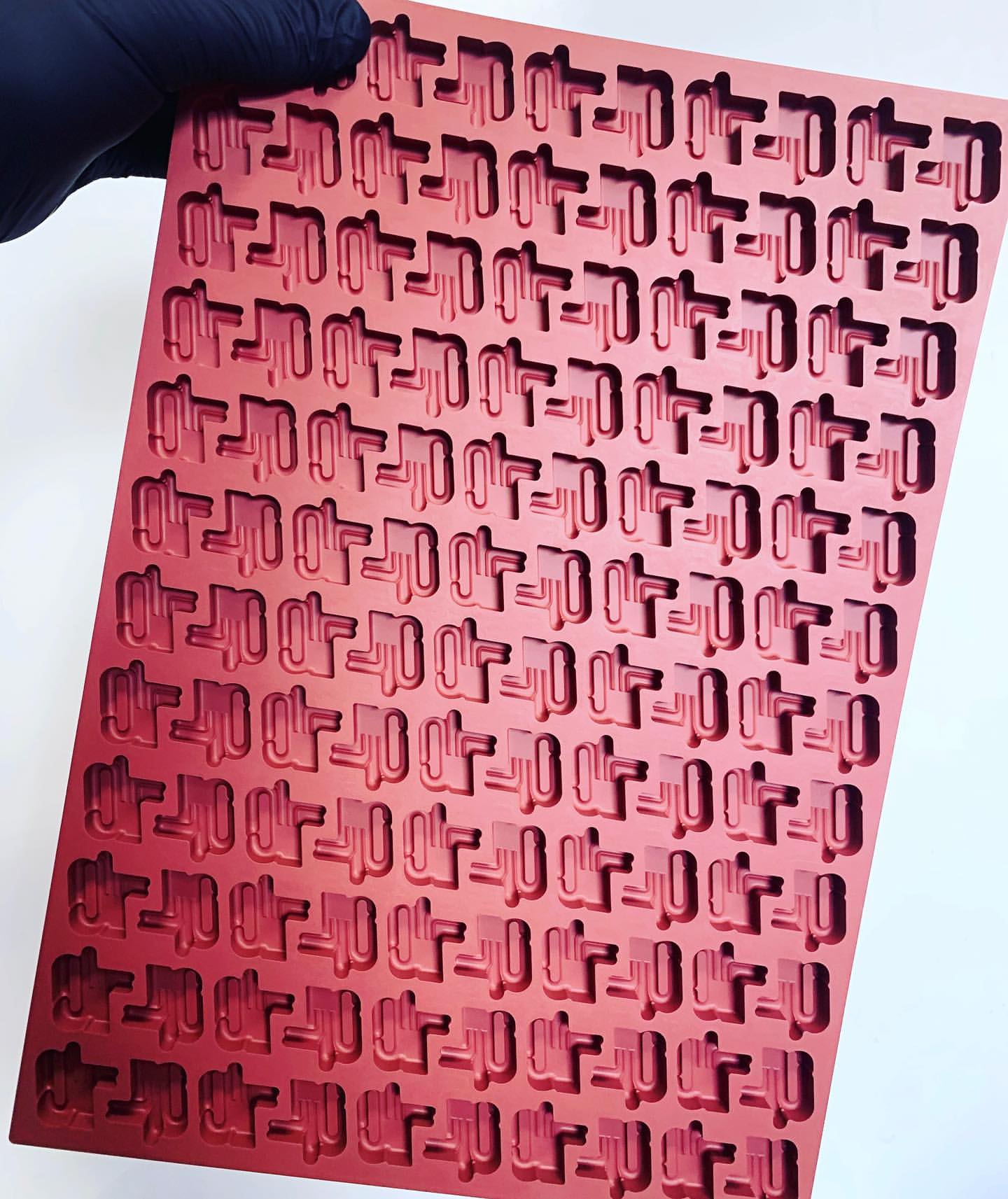

Creating a custom candy mold with a specific count, such as ten individual gummies, arranged in a connected configuration - such as a five by two pattern.

By demolding the gummies in these configurations and packaging them accordingly, the end-user can easily tear off the desired quantity.

Congratulations! You just reduced your counting costs by a factor of ~10.

Definitely something to keep in mind right?

For more efficiency-enhancing tips, check out our Instagram page. We’re regularly posting reels (and blogs!) on a whole range of topics that are sure to be relevant for your business.

At Dark City Molds, we offer a number of stock molds with similar features as those described above that can streamline your packaging process.

And of course – we are always open to incorporating this concept into a custom design that aligns with your unique brand vision.

It's crucial to consider how you want to present your brand and how the task of counting gummies for packaging aligns with your priorities.

While the hack I mentioned can reduce counting expenses, it's essential to evaluate its compatibility with your regulatory framework and desired brand image.

When it comes to packaging gummies, it's important to find a balance between efficiency, cost-effectiveness, and brand presentation.

Using a connected cavity configuration can significantly reduce the time and expense associated with hand counting -- and it looks good too -- making this an ideal solution for finding that balance.

So if you're ready to enhance your gummy packaging workflow and explore options like our stock molds or custom designs, we're here to assist you.

Reach out to us today to discuss how Dark City Molds can optimize your gummy production process.

Let's create a seamless experience for both you and your customers.