There is something incredibly exciting about the blossoming cannabis industry. People from all walks of life, in all kinds of careers, can develop an innovative product idea and then actually make it happen. Some of today’s most successful brands were started in a home kitchen, on evenings and weekends and with funding from friends and family.

A home kitchen is a great place to start and test ideas. If you’re looking to launch a successful and scalable gummy brand, here are the building blocks that will take your product from the minor league to the all-star team.

I. Recipe

First and foremost, any gummy needs to have a palate pleasing recipe. If the product doesn’t taste good, the customer will not make a repeat purchase. But there is more to a gummy recipe than just its taste, and oversights at the development stage can lead to major problems later. The key is to use a recipe with structural integrity. Making a gummy is essentially a process of structuring water molecules with protein chains or gelling polysaccharides to form a reliable solid. If the recipe is not created with the entire operations and distribution process in mind, then those water molecules may move around, and your customer will not experience the same quality product you shipped.

For example, it may not be an issue if your recipe takes a very long time to set in your home kitchen. When you start to scale, this kind of holdup can create bottlenecks in production that will cost you significant time and money. Likewise, if your homemade gummies are eaten soon after production it may not matter that they sweat or melt over time. However, as you scale and stock products on dispensary shelves, this flaw in the recipe could ruin the entire batch and lose you the trust of your retail partners.

Developing a recipe with structural integrity requires a detailed understanding of your ingredients. The choice between gelling agents such as gelatin and pectin will have a significant impact on the structure of the gummy both during production and once it’s on the shelf. Certain gelling agents are pH or ion sensitive; the complexity of these considerations can increase exponentially as you add more elements.

Another important consideration in the recipe building process is the quality of your active ingredient. If a gummy does not perform as advertised, or performs inconsistently, customers will not come back. Using a high-quality emulsion will help ensure that potency remains consistent, evenly distributed and shelf stable.

Starting out with a scientifically sound and high-quality recipe demands a larger initial investment of time, but it will pay off by averting costly roadblocks during production and distribution.

II. Molds

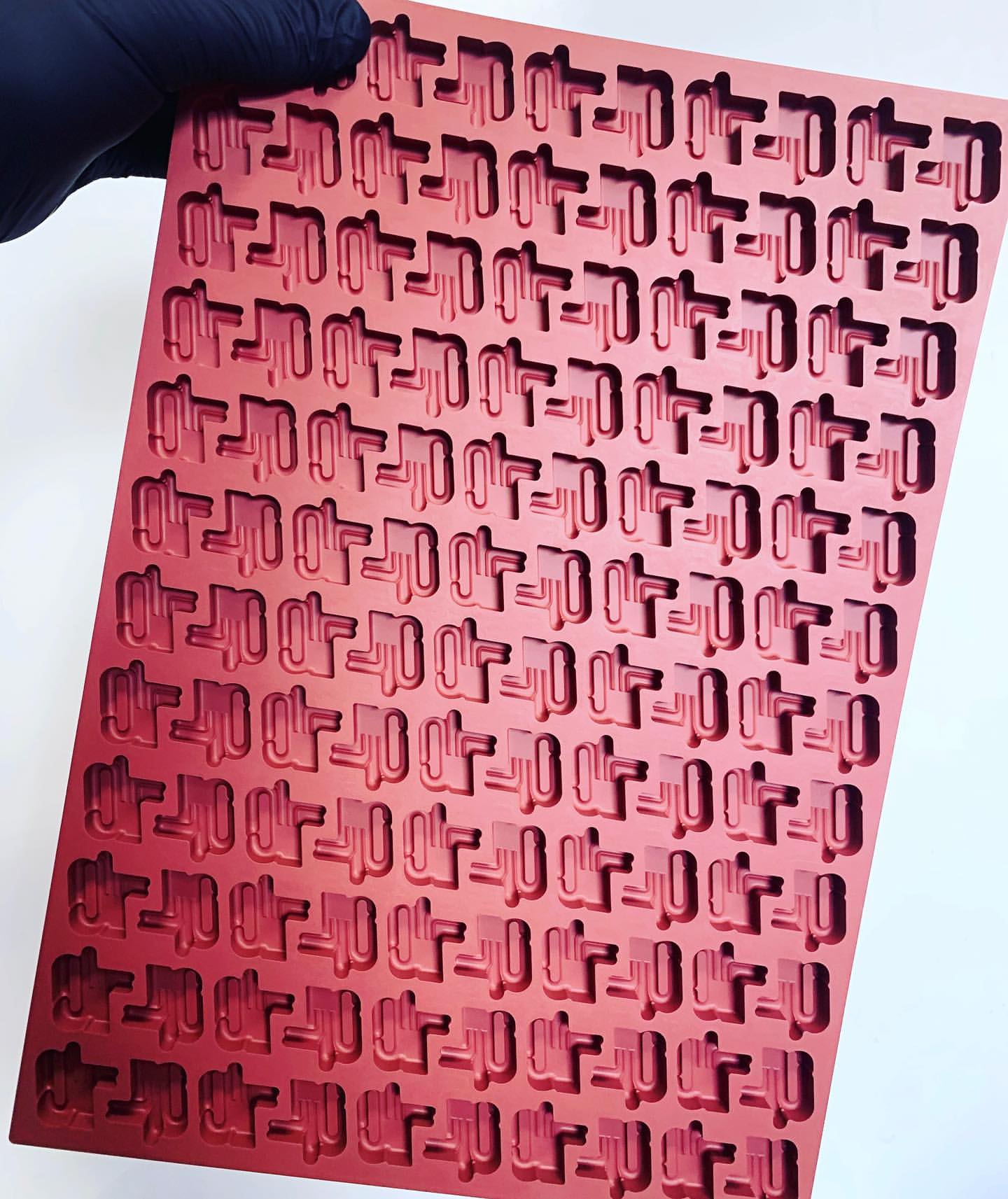

In the home kitchen, molds are one piece of a much larger gummy puzzle. However, like the recipe, failing to plan ahead when it comes to molds can lead to expensive and time-consuming mistakes once you start to scale.

During the production process, molds are the primary vehicle for efficiency. Not only do they enable the manufacturing of large quantities, but their design can also have a significant impact on workflows and labor costs, particularly when it comes to extracting the gummy from the mold. The de-molding process can take up to 70 percent of labor operations, so efficiency matters. To avoid slowing production speed, increasing labor time, adding additional steps, and spending more money over time, here are a few things to watch out for:

- If a mold is not designed for high volume production, it may require that each gummy be extracted one at a time which can dramatically decrease your de-molding efficiency

- If a mold requires oil or a de-molding agent to properly extract, it can complicate your process by adding extra steps (like clean up!) and hazards (slippery floors!)

- If the mold is poorly designed, the de-molding process itself can risk deforming the gummy due to increased “wall drag”

- If the mold is not made with durable materials, it may wear out prematurely and require more frequent replacement

In short, the quality of your molds makes a big difference. Molds that are enjoyable to work with keep your workers happy and result in lower turnover rates, which can be a costly and time intensive aspect of running a commercial kitchen.

Molds can be a significant investment, and while it is important for those just starting out to be cost conscious, it’s better to buy fewer of a quality product than build your process around the wrong one. It is also important to think about your mold’s return on investment based on price-per-cavity versus price-per-mat. Certain molds may seem much more affordable, but they also produce fewer gummies.

As you continue to scale your brand, do not forget to think about a mold’s ROI. Molds are equipment, not accessories, and starting out with high quality equipment is a sure path to a dependable ROI.

III. Operations

When brands begin to scale, operations are top of mind. Locations, equipment, schedules, and staffing are all vital considerations, and can seem straightforward. However it’s easy to make big mistakes at this stage.

These mistakes most commonly stem from the order in which operations decisions are made. Many brands will purchase thousands of dollars of equipment, for example, without considering their recipe, mold design, business model, and preferred workflows. In reality, the recipe and molds themselves are intricately connected to the kinds of equipment and workflows needed. It’s futile to have a state-of-the-art depositor if it doesn’t meet the needs of your recipe or if you’re losing your efficiency advantage by using the wrong molds.

Similarly, if you do not have a clear picture of how long it takes your gummies to set, it’s impossible to estimate how much time you will need on location, or when to send in staff to begin demolding. At an even more basic level, if you do not know the ideal humidity for your gummies to set in, how can you be sure that a certain location is the best fit for your operations? At the end of the day, it is much easier to build your operation around recipe and molds than trying to retrofit those elements to work with a particular piece of equipment.

When bringing any new product to market, a brand needs to clearly identify its point of differentiation to earn attention from customers. Generally, a gummy can compete either on price through efficient production or on quality through innovation on flavors and ingredients. Whichever field your gummy competes on, the three considerations outlined in this article will be vital to making a sustained impact.

By Lauren Tamburro & Evan Smith