As I’ve written about elsewhere in this blog, when it comes to setting up a professional gummy kitchen, having a solid gummy formula is a necessity.

But an often under-considered aspect of establishing scalable operations is making the right equipment choices for your professional gummy brand.

And one essential piece of equipment that plays a central role in gummy manufacturing is the cooking kettle.

While there are various configurations available, one configuration stands out as the clear best choice for most operations – especially for companies just starting out who want to stay lean and mean.

This is why I am constantly suggesting that my clients start with three kettles.

In this blog, we will explore the reasons why investing in three cooking kettles is the optimal configuration for your professional gummy kitchen.

From streamlining production to maximizing productivity, let's delve into the advantages of this setup and discover how it can elevate your gummy-making operations to new heights.

And for more information about all things gummies, be sure to check out our Insta.

The Best Way to Set Up Your Professional Gummy Kitchen

The long and short of it is this: having 3 kettles (like the excellent Firemixer 14) tends to be the sweet spot that enables you to create overlapping cooking rotations.

Think about the anatomy of a batch.

While cooking, you’ll want to grid out your molds, and then as soon as the cooking session is over, you’ll be pouring the gummy mixture onto the molds, scraping the excess into the cavities, placing the molds on a speed rack and relocating them to cure, and then cleaning up.

Let’s say the whole process takes 1 hour 20 minutes - 1 hour cooking time, and 20 minutes for everything else.

With only one kettle, even if you start cleaning it immediately after pouring your slurry, you still have to wait the entire duration of the second cook to be able to pour your second batch.

Assume it takes 10 minutes to transfer the slurry to the molds and clean the kettle thoroughly, this means, even with max labor efficiency, that your top speed would be 1 batch for every 70 minutes.

But with 3 kettles, you can stagger your cooking sessions, nearly tripling your output, without necessarily expanding your team.

Let me explain.

The Ideal Kitchen Rotation for Gummies

Here’s how it would work: you start cooking your first batch, then after 20 minutes you start the second, and again 20 minutes later, the third.

Why 20 minutes? Because in our hypothetical that’s how long it takes on the backend for the gummy slurry to be flooded & scraped, the filled molds moved for curing, and new empty molds laid out.

You’ll have to adjust based on the specifics of what you’re able to achieve with your team. But the upshot is this:

With staggered cook start times, the second batch can be ready to pour as soon as the molds are on the table.

Same with the third.

Cooking Gummies at Scale - The Smart Way

So consider a hypothetical typical cook day with 3 kettles:

At 9am, start cooking the first batch. At 9:20am, the second batch. At 9:40am, the third batch.

At 10am, the first batch is ready to pour. After 10 minutes, kettle #1 is emptied, cleaned and ready for reuse - so by 10:10am, you can use kettle #1 to start cooking the fourth batch.

At 10:20am, the filled molds for the first batch are removed, and the second batch is ready to pour. By 10:30am, kettle #2 is used to start cooking the fifth batch.

At 10:40am, the filled molds for the second batch are removed, and the third batch is ready to pour. By 10:50am, kettle #3 is used to start cooking the sixth batch.

At 11am, the filled molds for the third batch are removed, and your workers can take a well-deserved 10 minute stretch break!

At 11:10am, the fourth batch is ready to pour…

And by now, I think you know the rest.

After that first hour of the day spent only cooking, staggering your cook times in this manner allows you to achieve an output of 1 batch every ~23 minutes, all while optimizing labor utilization and minimizing downtime.

And this is why it’s the best solution for most operations.

Now you may ask “Why stagger them though? Why not do 3 (or more) simultaneous batches? Wouldn’t that be best for maximizing output?”

And the answer is, well yes it would be, and you should most certainly do things this way if you have a big enough team to run that setup.

But the crucial math for you to consider is: at what point do the increased labor requirements outweigh the gains in efficiency?

What I and my clients have found is that this point of diminishing returns starts somewhere after that third kettle.

Of course, there are a lot of moving parts, and changes in some of the foundational variables – like the time it takes to cook a batch, for example – can have a profound effect on this math.

But at the end of the day, for my lean mean clients – investing in 3 kettles and staggering the cooks is absolutely the way to go.

—

Investing in three cooking kettles for your professional gummy kitchen may initially seem complex, but the benefits it brings are worth every consideration.

Once you have mastered the intricacies of this setup, you will appreciate the foresight in addressing its complexities upfront.

With fewer risks and greater efficiency, your gummy-making operations will flourish, allowing you to focus on creating high-quality products without compromise.

For a deeper dive into kitchen and cooking considerations, explore our comprehensive Recipes & SOPs.

These invaluable guides go well beyond the scope of this blog, providing detailed insights and solutions to simplify the challenges you may encounter along the way.

We call them the Gold Standard for a reason.

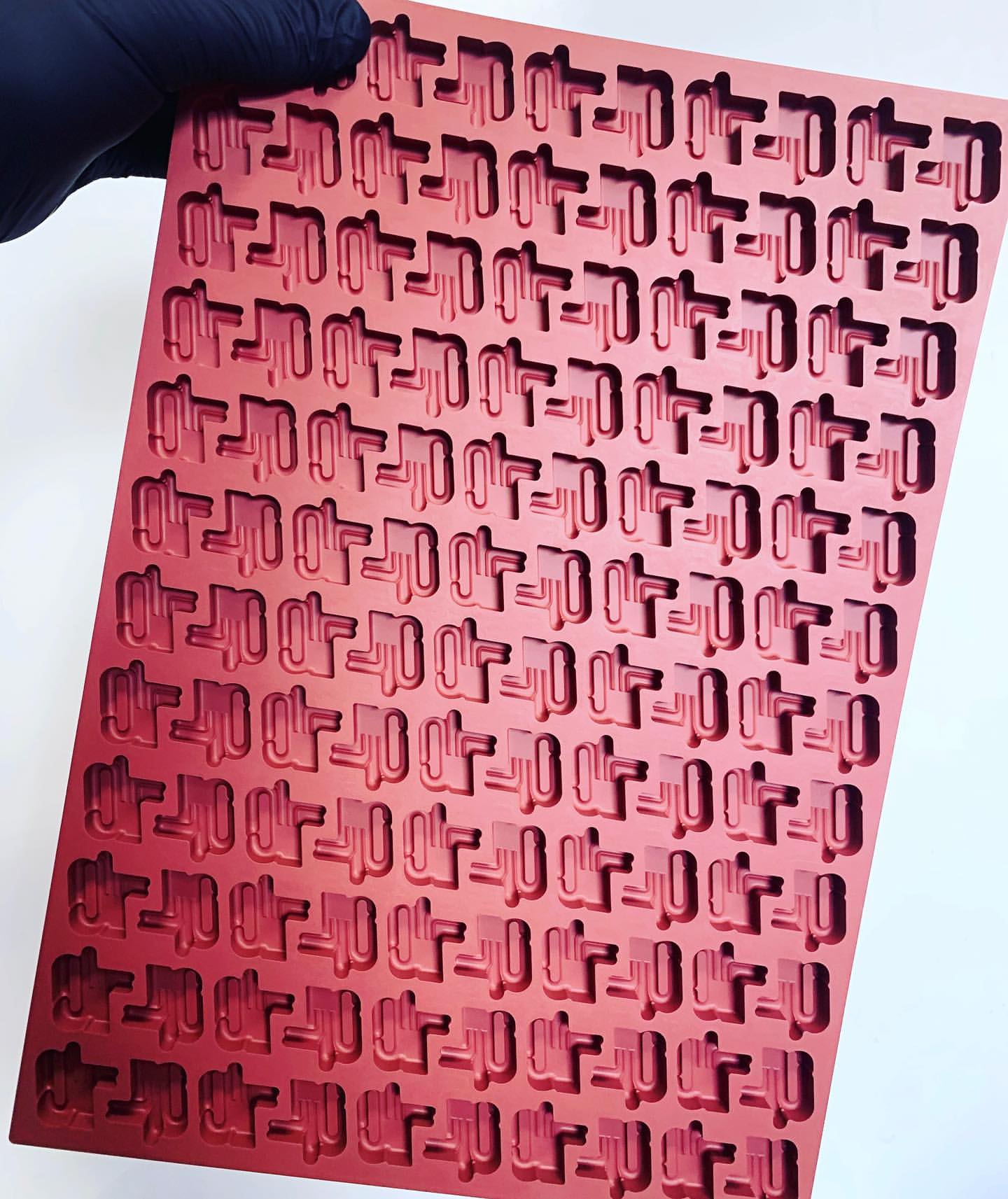

And be sure you’re not bottlenecking production at the demolding stage! Browse our selection of performance-grade platinum silicone Rose Pro molds. These molds ensure consistent, efficient throughput and precise shapes, allowing you to create gummies that are both visually stunning and delicious – at scale, at speed.

Have a creative idea for a custom shape that will make your brand pop? Don't hesitate to reach out to us today. Our team of experts is ready to assist you in turning your vision into reality.

Your journey towards gummy greatness starts with Dark City Molds.